Heavy equipment is a major investment for any organization. When machinery starts showing issues, you want to address them in the most economical way. While repairing a machine might have a lower upfront cost, sometimes equipment overhauls can be better in the long run. It’s important to understand factors like finances, the equipment’s age and its condition before making a decision to replace or repair.

As equipment ages, it will require more repairs. The 50/50 threshold rule can help you decide when to replace equipment. It states you do not need to replace a machine until its repair costs exceed more than half the cost to replace. While it’s a helpful rule in some situations, the point of failure can look different depending on the machinery.

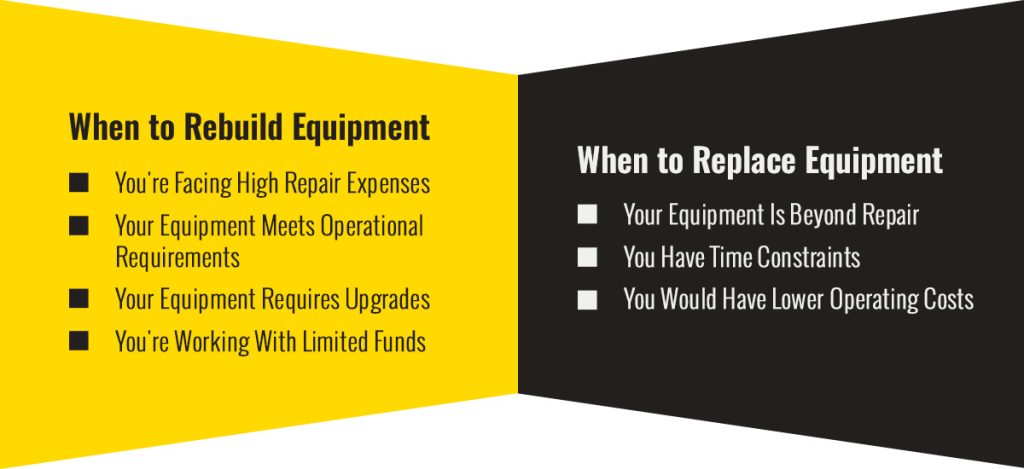

The following factors can inform your decision to replace or rebuild equipment:

Rebuilding involves swapping out your equipment’s major components and minor elements. The process can restore your equipment to like-new condition and extend its life span. Rebuilding is often the more cost-effective, long-term option. Instead of carrying out multiple repairs, you can upgrade everything at once, including the engine.

Rebuilding might be the better option in these scenarios:

Rebuilding can be more cost-effective if the price of repairs exceeds the cost of rebuilding by more than half its value.

Rebuilding can give your construction equipment a second life. If it already gets the job done, rebuilding may lead to better results than a complete replacement.

If you want to accomplish more with your equipment, rebuilding may be better. Rebuilds allow you to upgrade your equipment. For example, you can fit it with newer technologies and accessories to improve its performance.

Rebuilding is often the less expensive option compared to a new equipment purchase. Many companies that offer rebuild services provide financing options to make it even easier to afford.

Weigh the pros and cons to determine whether you should rebuild your construction equipment. Rebuild benefits include:

While a rebuild can deliver optimal results in many scenarios, it can come with some cons:

Here are some signs you might want to replace your equipment rather than rebuild it:

If your equipment is old or has several mechanical problems, it might cost more to repair than replace. In this case, investing in a high-quality used product may provide a negligible price difference and better long-term performance results.

Rebuilding a piece of construction equipment can be a lengthy process, especially if it requires more extensive work. If your organization cannot afford the downtime, you might consider replacing the machine by purchasing it new, used or investing in a long-term rental.

Rebuilding may provide improvements in performance and efficiency. At the same time, these upgrades might not match what a new product can deliver. While initial costs may be higher, a replacement could have a more meaningful impact on your company’s bottom line.

The benefits of replacing your machinery include:

Drawbacks of equipment replacements include:

When it comes to replacing vs. rebuilding machinery, consider your finances and your specific equipment issues. If you’re having trouble deciding the right course of action for your specific situation, Puckett Machinery can help. We offer new construction equipment and rebuild options to help you boost productivity and stay within budget. Our highly trained technicians ensure our rebuilds are as close to a new Cat® machine’s quality as possible.

Whether you’re looking for new, used, rental or rebuild options, let us partner with you to meet your unique needs. Contact us to learn more about our services.